- Home

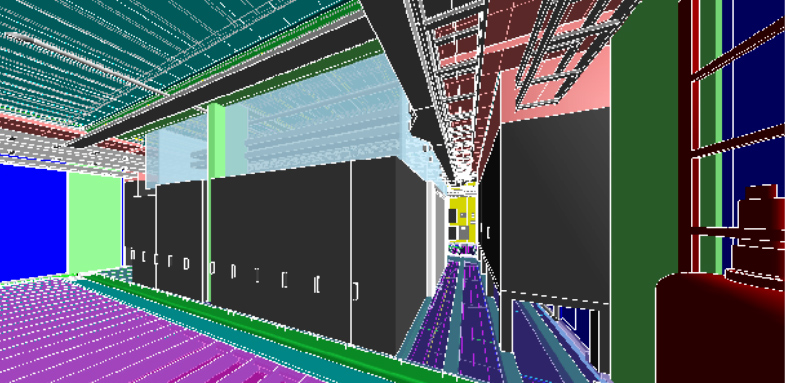

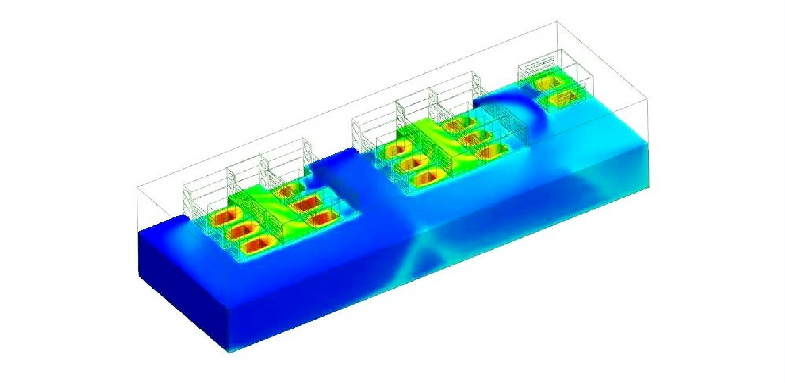

- Product

- Solution

-

News

News

Stay updated with the latest developments of CIMC Xinhui

Timely dissemination of real-time industry news

Documenting the robust growth of CIMC Xinhui

-

About

About

Wholly-owned Subsidiary of CIMC Group

National High-Tech Enterprise

Container Manufacturing and R&D Base in the Guangdong-Hong Kong-Macao Greater Bay Area

-

Contact Us

Contact CIMC

Welcome to contact us anytime and anywhere

Honesty is the first step in cooperation

Please leave a message online if you have any question